[Phnom Penh, Cambodia] Huawei released the industry-first FTTM all-optical factory solution based on passive optical network (PON) technologies. This solution can help customers build highly reliable industrial networks to improve production quality and efficiency.

With the continuous deepening of the digital transformation of manufacturing enterprises, concepts such as “smart factory” and “black light factory” have emerged one after another. The essence is that manufacturing companies need to rely on continuous improvement of ICT technology to meet the needs of stable data connection and deep integration to realize the digitization, networking, unmanned and intelligentization of factories. In this smart manufacturing race against the background of digital transformation, network infrastructure, as the base of digital technology, has developed into a key factor that cannot be ignored in determining the success of manufacturing companies in promoting smart manufacturing. FTTM (Fiber to the machine) uses optical fiber as the communication medium, and has the advantages of deterministic experience, ultra-large bandwidth, safety, reliability, and green energy saving. It can help manufacturing companies realize the integration of intelligence and scenarios, as well as stable connections. It has become a strong guarantee and important support for realizing the release of data value in the process of digital transformation of manufacturing enterprises.

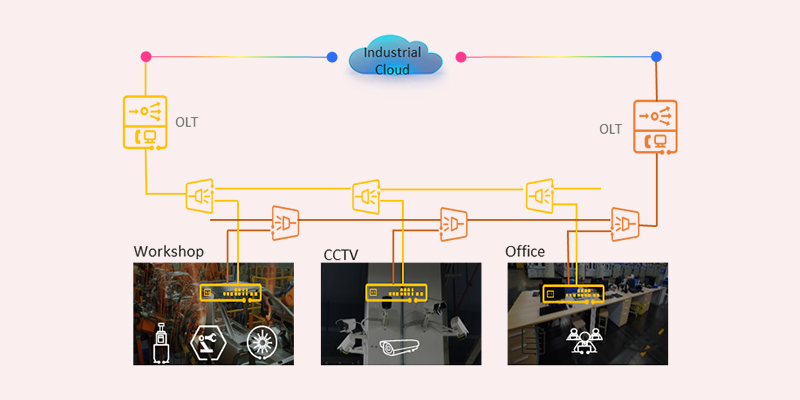

In the field of manufacturing, Huawei continues to develop industry application scenarios, and has created an FTTM all-optical factory solution. OLT and ONU equipment that realizes P2MP connection through passive optical splitters, providing manufacturing enterprises simple architecture, easy evolution, intelligent O&M, and highly reliable production network. The FTTM all-optical factory achieve three innovations: 0 EVL Cabinet Deployment, Cabling once for 10 years, and 1-engineer O&M.

0 EVL Cabinet Deployment: The solution is architecture revolution. The active OLT is located in the data center, the ONU is close to the access information point, the middle is completely passive, and the transmission distance is as high as 40 kilometers. In addition, the optical/electrical composite cable can also support remote power supply of the ONU. The workshop does not need to deploy cabinets, and the overall deployment efficiency can be increased by 30%, and it can easily carry ultra-long production lines.

Cabling once for 10 years: The solution uses optical fiber instead of traditional network cables as the transmission medium. The optical fiber is made of silica, which is very stable, corrosion-resistant, and anti-electromagnetic interference. The bandwidth of the optical fiber is unlimited, and it is easy to transmit the imaging data of the industrial camera (gigabit), which can be smoothly evolved to 50G or even 100G. TCO can be reduced by 30%.

1-engineer O&M: Production, office, and security services are integrated into one network, and a single optical fiber network is carried in a unified manner. Passive components are free of operation and maintenance and have an extremely low failure rate. The “eSight” can manage devices on the entire network in a unified manner, enabling end-to-end O&M visualization of the entire network, improving O&M efficiency by 60%. 1 person can easily manage the entire plant.

The solution can also be used to build reliable, flexible, and efficient all-optical networks that meet requirements of high reliability, precise control, and super-distance coverage. It can be used in a wide range of scenarios, including factories, subways, highways, ports, electric power, intersections, and mines.

This year, Huawei launched the solution in Cambodia based on the 2021-2035 Digital Economy and Social Policy Framework. Huawei will cooperate with various industries in Cambodia to promote digital transformation in Cambodia’s industrial sector.